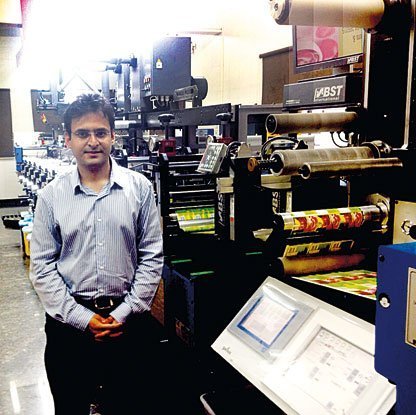

JK Labels cuts down waste by 7%, eyes expansion

'Frail' lip tint casing is a technical triumph for pcr plasticsRocket science for lip gloss – effort and try again

A global business specializing in handmade beauty and cosmetics, Lush believes information technology has fabricated a technical advance by producing a lip tint with a casing that shows the potential of 100% post consumer recycled polypropylene (pcr PP) in a challenging 'fragile' application.

Lush'due south recently launched lip tint with 100% pcr PP casing

Speaking to Packaging South asia, senior buyer at Lush, Gabbi Loedolff, said, "The twist, air current up and down mechanism is fragile and presents challenges for both the material and manufacturing process."

With more than 900 stores in the UK where it is based and around the world, turning over in excess of 450 meg pounds annually, Lush considers end of life at the start of whatever new production development. The empty lip tint applicator needed to be made of a single material to be easily returned into a closed loop, the supply source of pcr PP resin.

"Proving its feasibility, showing it can be washed," was a big obstacle, as was "to convince the manufacturer in the US to trial it and then to be pleased with the outcome," said Loedolff.

Explaining why developing the product was a major claiming, Loedolff said, "We needed an item of packaging with a twist mechanism, in a unmarried material, that would permit the product to be poured in, rather than moulded and then inserted, mainly from a product and formulation perspective. Lip product containers, especially wind upwards and down ones, are often made from a combination of plastics, which would make it hard for customers, or united states, to recycle at the end of the production's life. We plant a company that had a tool that would piece of work, but they had previously trialled pcr PP with no success.

"We were able to work together to provide them with samples of the material nosotros apply and they consented to running another trial, although they were non hopeful that it would succeed. The trial was successful and they are now able to produce a pcr PP slice of packaging that tin can feed back into our closed loop."

Lush hopes it is changing perceptions of what is possible with pcr plastics. The next hurdle is to find a fabric converter and a manufacturer with compatible tooling on the same side of the Atlantic Body of water. For technical reasons Lush currently uses a textile converter based in the U.k. and has to ship the source recycled resin to the US for industry into the last product. "We shouldn't exist shipping it elsewhere. Nosotros're looking for a local source of material in the US that works with the manufacturer's tooling," said Loedolff.

The lip tint with 100% pcr PP casing was recently launched at the largest Lush store in the globe, the UK flagship in London's Oxford Street, and will be rolled out globally for Christmas ranges. In April 2022 Lush opened a waste material hub in the UK to regrind incoming PP from its bring-dorsum scheme.

Source: https://packagingsouthasia.com/type-of-packaging/labels/reducing-wastage-optimizing-costs/

0 Response to "JK Labels cuts down waste by 7%, eyes expansion"

Post a Comment